ODM

Empowering your brand with our top ODM open ear headphone solutions

With an experienced R&D team, by comabining marketing, design and technical services, ALOVA helps clients maximize brand value, expand product portfolio and provide professional & efficient services.

Design & Engineering Process

At ALOVA, from concept to completion, our expert design and engineering team works closely with you to create innovative open-ear audio solutions tailored to your specific needs, ensuring precision and efficiency at every stage.

Marketing Dept. and R&D Center

- Concept Study

- Solution

- Proposal

- Spec Proposal

- RFQ

- Launch Plan

Marketing Dept. and R&D Center

- Project Team

- Schedule

- Milestone

- Design

- Mock-up

- Making

- Sound Tuning

- Function Test

- Mechanical Design

- Tooling Design

- Capacity Evaluation

- DFEMA (Design Failure Mode and Effect Analysis)

- Tooling 0-2

- Design Verification

- Reliability Test

- Function Test

- Sound Tuning

- SOP

- Jigs

- Reliability Test

- Function Test

- Capacity Forecast

- Short Run Production

- Inspection

- Reliability Test

- PP Confirmation

- Mass Production Sample Confirmation

- Prodution

- Inspection

- Shipment

Our Team

Our team of audio experts and engineers brings years of experience in developing innovative open-ear products, driving us to create the best in bone and air conduction technology.

Engineering Department

Production Line

Supply Chain Department

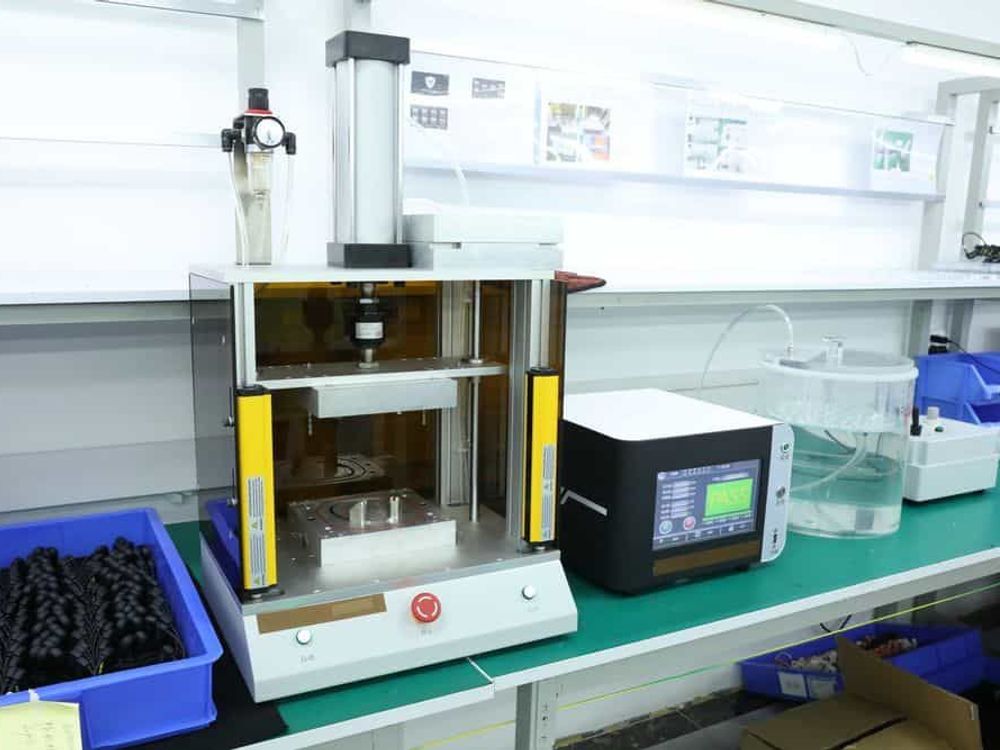

QC Equipments

Equipped with advanced testing tools, our quality control machinery ensures that each product passes rigorous checks for durability, sound quality, and reliability.

Button Life Testing Machine

We simulate normal button usage by adding a 200g weight and pressing the button 3,000 times, then verify its functionality.

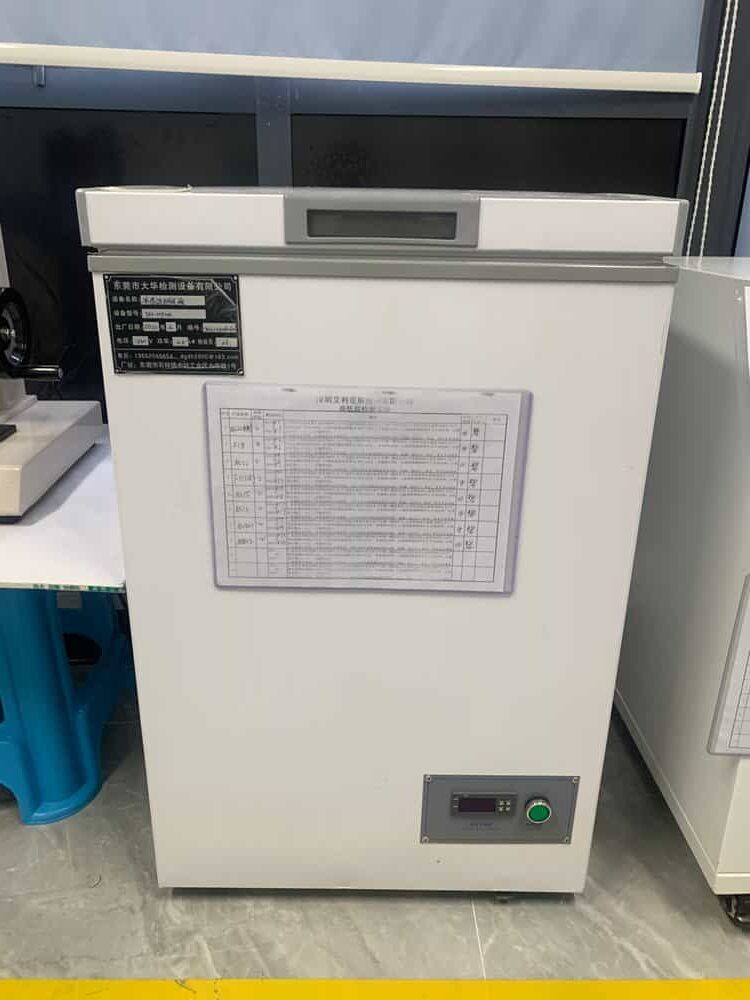

Temperature Cycling Test Machine

Place the Bluetooth headphones in a temperature chamber at 70°C ± 2°C, play music, and hold for 2 hours; then lower to -20°C ± 2°C for 4 hours, with a transition time under 30 minutes. Repeat for 5 cycles, inspecting for defects, cracks, or fire, and test all functions. Passing products proceed to the next process.

Drop Test Machine

Drop the product from a 1m height onto a cement floor (6 sides, once per side) to check for cracks or looseness, then test electrical functions, buttons, indicator lights, and sound; passing products are sent to the next process.

Simulated Vehicle Transportation Vibration Tester

Vibrate the product at 100Hz for 10 minutes, then inspect seams and joints for cracks or looseness, and test electrical functions, buttons, lights, and sound; passing products proceed to the next process.

Charging Port Durability Testing Machine

We simulate normal magnetic charging by using a charging cable 1,000 times at 10–20 presses per minute, then check the charging port’s functionality and contact; if it still connects magnetically, the product is considered good.

Wire Bending Test Machine

The wire bending machine tests six products at once, clamping each wire, applying a 1000g weight for tension, and rotating at 20 RPM for 1000 cycles. Inspect for damage or stretching, and test load-bearing limits; wires with no damage are deemed good and proceed to the next process.

Battery Capacity Grading Tester

Clamp the battery terminals onto the tester (capable of handling eight products simultaneously), power on, and the eight LEDs will blink. Open the “LiBatTest” software, set discharge and charge steps matching battery capacity, and start the test. The computer will display battery capacity and voltage, with a white checkmark indicating completion. Passing products proceed to the next process.

Salt Spray Testing Machine

Metal components undergo a 24-hour salt spray test with a 5% NaCl solution (pH 6.5–7.3) at 35°C and 1.4 ± 0.2 Kg/cm². No corrosion should occur. Passing products proceed to the next process.

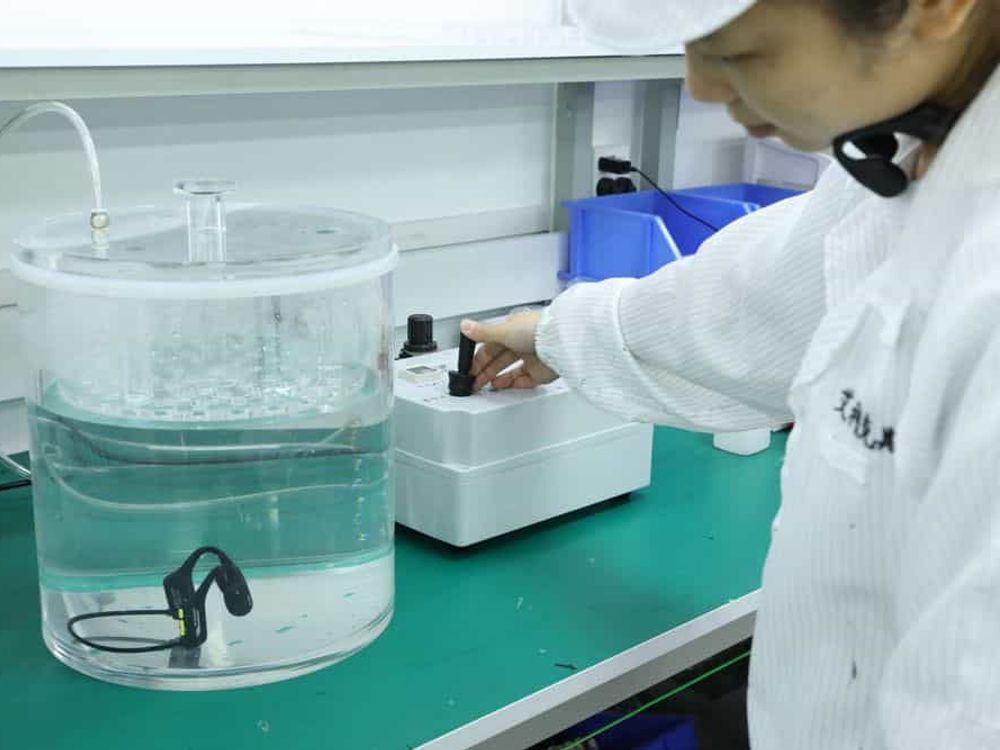

Leakage Detection Equipment

Place defective products from the IPX68 waterproof test into water, close the lid, and turn the controller switch to “Vacuum On,” ensuring the pressure gauge reads between 19–21. Continuous bubbling indicates a leakage point. After identifying it, turn off the vacuum, hold the exhaust button until the gauge reads zero, remove, and mark the leakage points after drying.

Bluetooth Multifunction Tester

The machine automatically connects to the Bluetooth headphones, which pair upon powering on. Test functionalities like call answering, voice control, battery display, track selection, play/pause, power on/off, and volume control, ensuring all displays and button functions work normally.

Charging Power Tester

After connecting the Bluetooth headphones, the tester will display the charging current and maximum power consumption.

Charging Aging Equipment

The foam-covered rack prevents scratching. Place the product gently and run the aging test for 1–2 hours. Ensure the charging cable magnetically connects properly (loose connections indicate a defect) and monitor the headphone indicator light: solid green means charging, white means fully charged. If green persists after 2–3 hours, the product is defective and requires further current analysis. Passing products proceed to the next process.

IP68 Waterproof Testing Machine

Inspect the product for scratches or stains, then place both headphone sides into the fixture, ensuring the neckband is fully secured. Press the start button until the upper mold descends, then release. A green “PASS” indicates a qualified product, while a red “FAIL” indicates a defect. Separate and label passed and failed products accordingly.

Testing Equipment for Hearing Aids

Test the gain levels across different frequency bands and the distortion of hearing aid headphones.

Clients Who Trust Us

We are proud to be the trusted partner of leading brands and businesses around the world.

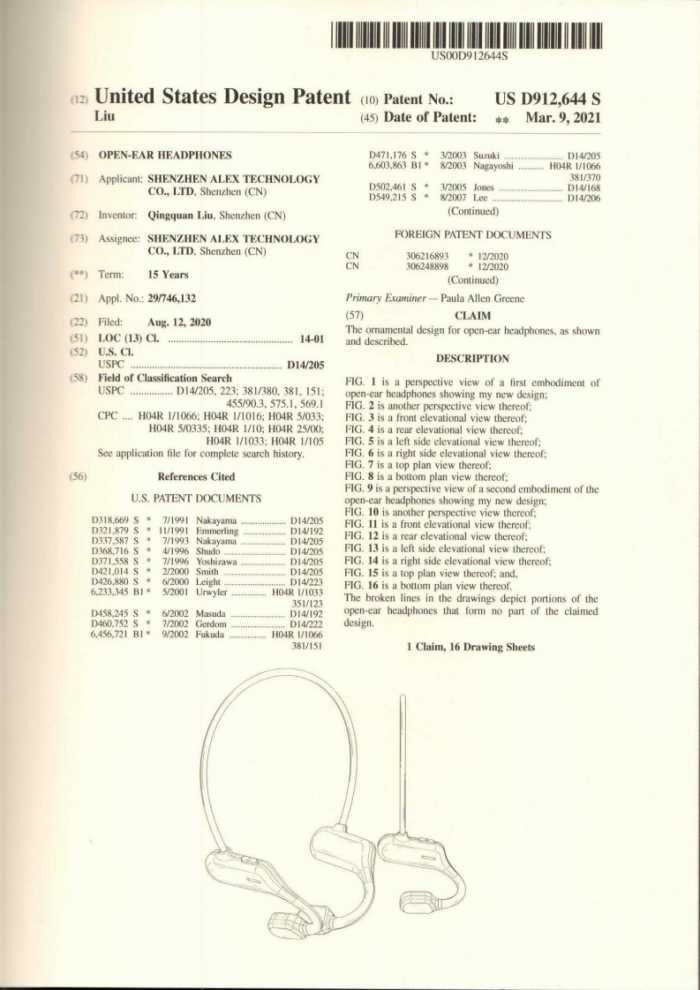

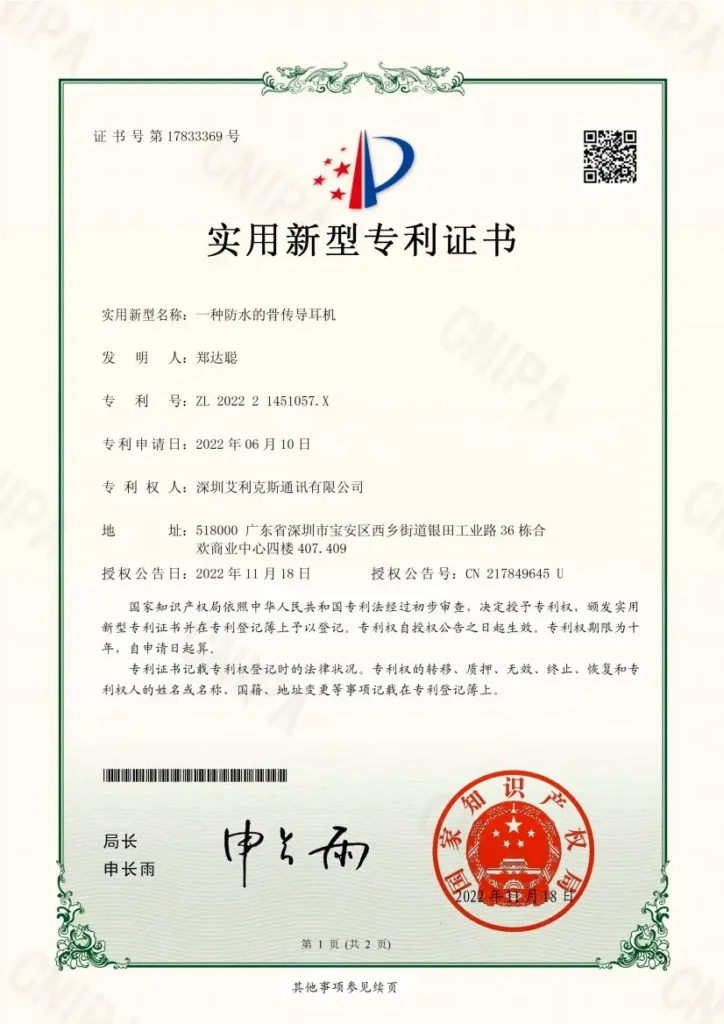

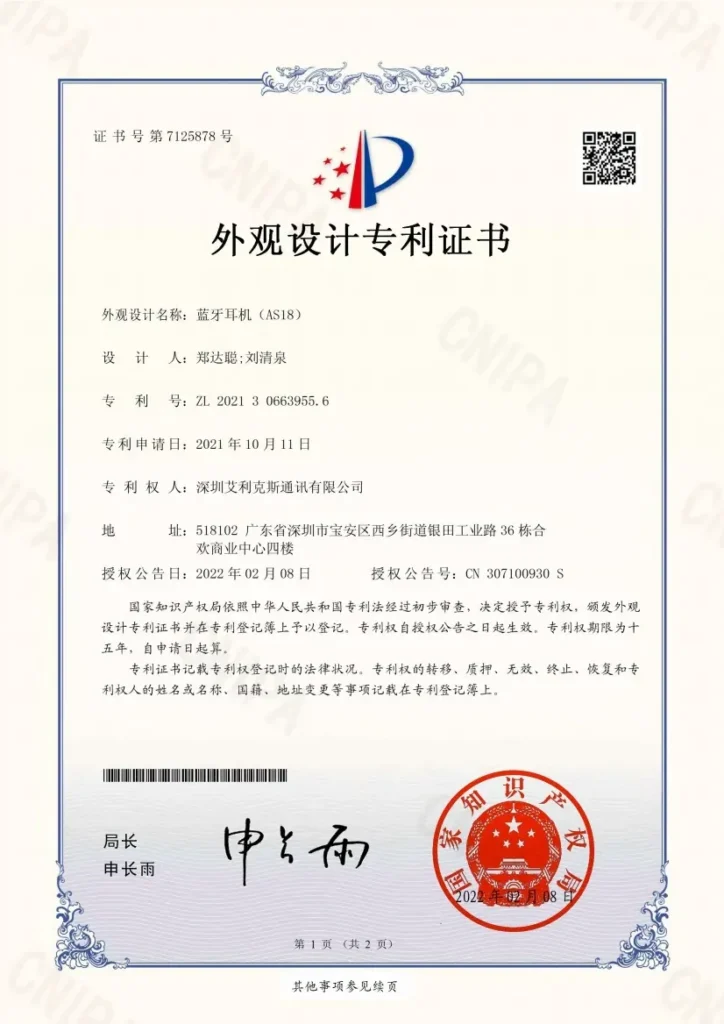

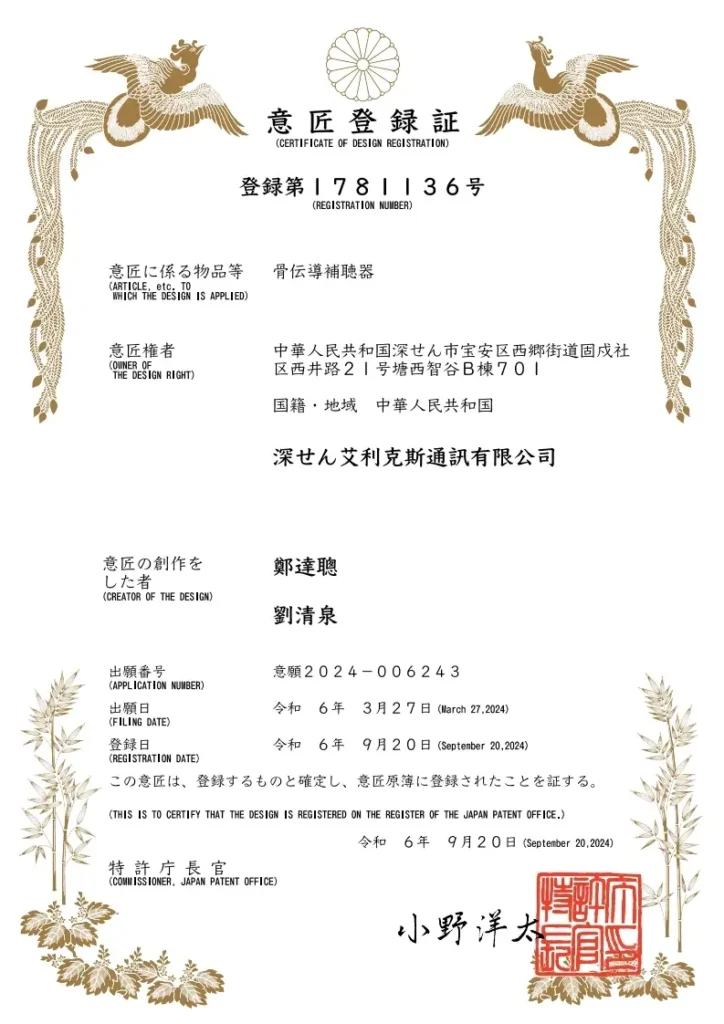

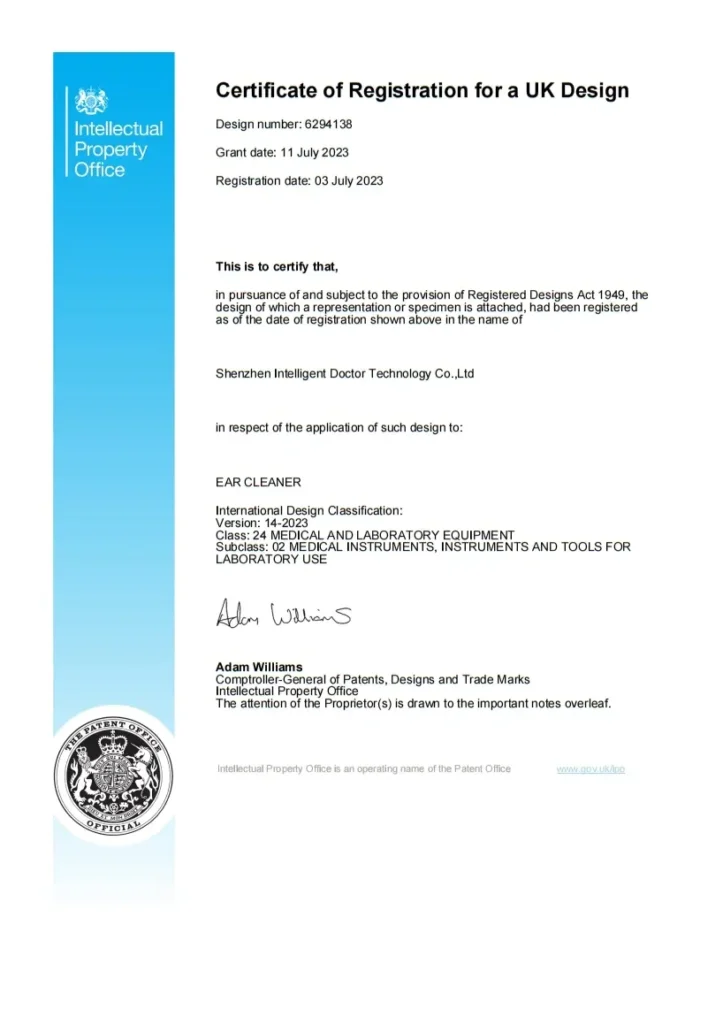

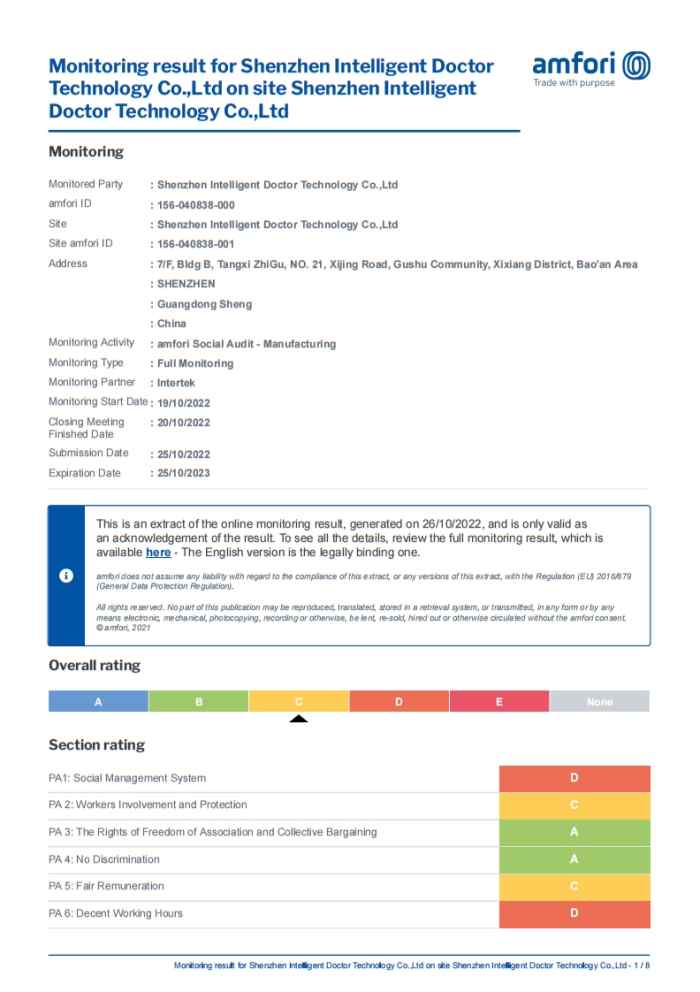

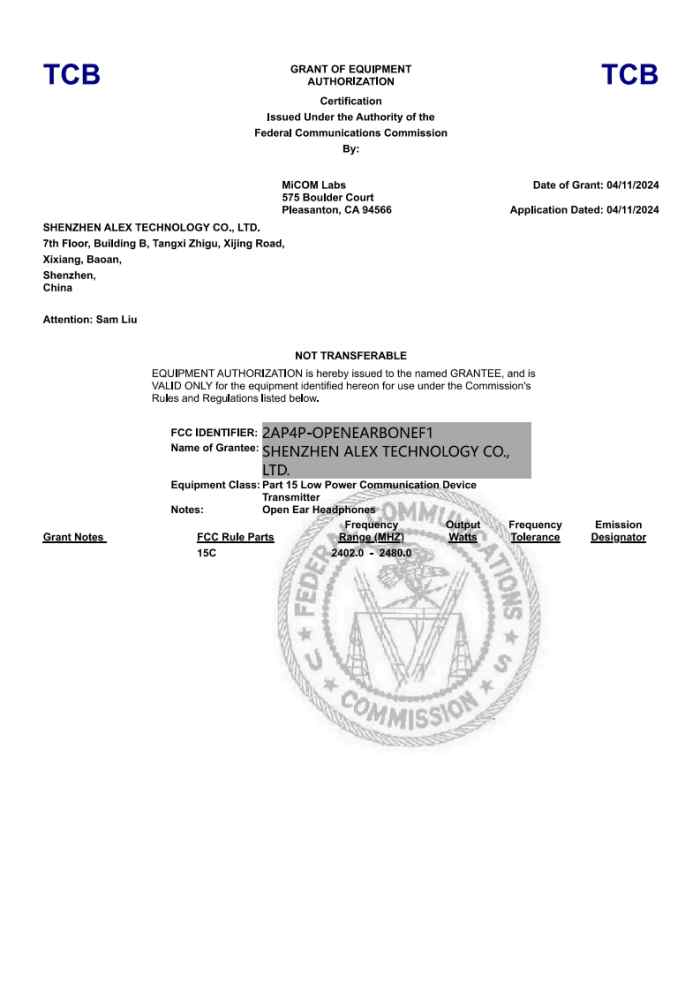

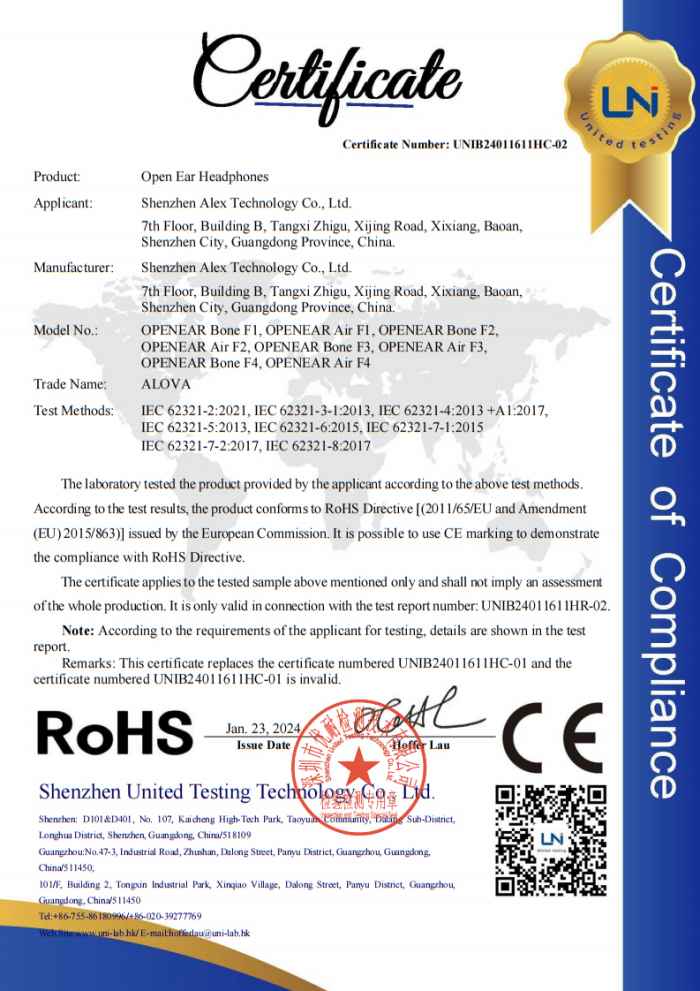

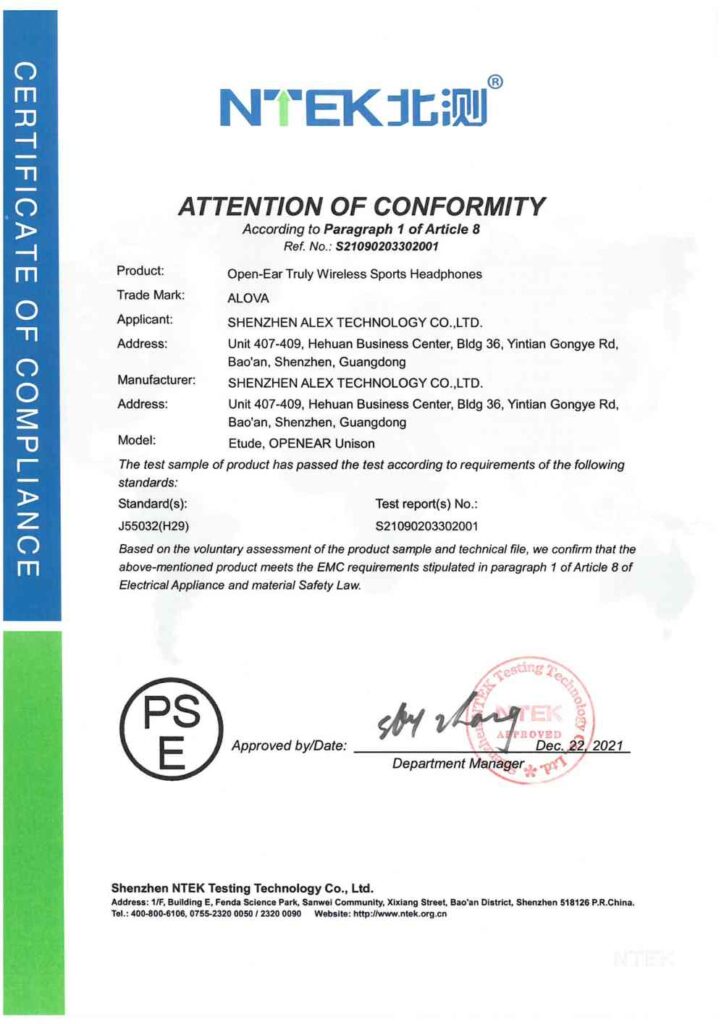

Certificates

ALOVA’s commitment to excellence is validated by our international certifications, guaranteeing that our open-ear products meet the industry’s highest standards for safety and quality.

(Click thumbnail to enlarge the certificates)

ODM Frequently Asked Questions

ODM (Original Design Manufacturing) services are comprehensive solutions we provide to clients, covering everything from product design to production.

You need to provide product concepts, design requirements, functional specifications, and market positioning information.

The order process includes the following steps:

- Concept Confirmation: Finalizing the product concept.

- Appearance Design: Developing the visual design of the product.

- Structural Design: Designing the product’s internal structure.

- PCBA Design: Creating the Printed Circuit Board Assembly design.

- Sound Tuning: Fine-tuning the product’s audio features.

- 3D Functionality Testing: Testing the product’s functions using 3D models.

- Mold Injection: Manufacturing the molds for production.

- Pre-Production: Producing initial batches to validate the manufacturing process.

- Mass Production: Scaling up to full-scale production.

Absolutely! We welcome clients to provide design concepts and collaborate with us to develop unique products.

Yes, our design team can provide technical support and design recommendations to assist you in creating your products.

Our minimum order quantity for ODM is typically 3,000 units, but this can be negotiated based on the product type and specific requirements.

The development cycle usually ranges from 14 to 22 weeks, depending on the complexity of the design and production requirements.

We recommend providing the initial design proposal within 1-2 weeks after project initiation to ensure timely progress in development.

We value our clients’ intellectual property and will sign a confidentiality agreement to ensure the safety of your designs and information.

We will provide design samples or 3D models for your confirmation. Once approved, we will proceed to the production phase.