Sample Price

$69.00

| Product Type | TWS in-ear hearing aid headphones |

|---|---|

| Bluetooth Phone Call | Supports Bluetooth connection for high-definition calls. |

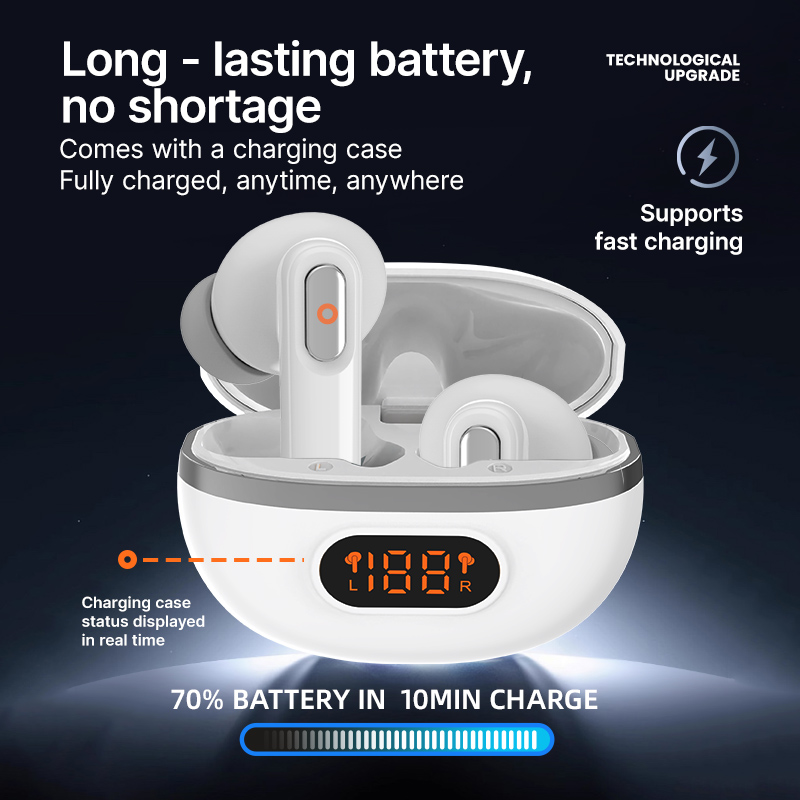

| Auxiliary to time | ≥ 8 hour |

| Battery (Earbuds) | 45mAH |

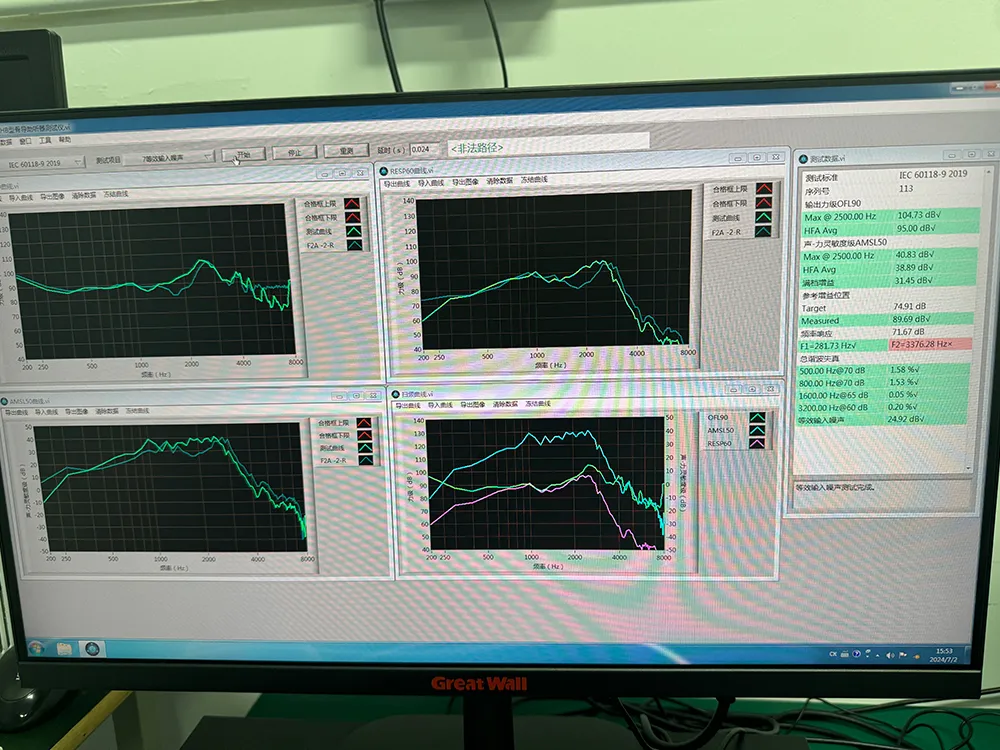

| Maximum gain | 31±3dB |

| Full-range average gain | 28±3dB |

| Average gain | 28±3dB |

| Harmonic distortion | ≤ 3% |

| Charging Time | 1H (earbuds) + 1.5H (case) |

| Charging Input | TYPE-C DC-5V/1A |

IP waterproof and dustproof ratings (Ingress Protection Rating) are used to indicate the level of protection an electrical device has against dust and water. The IP rating consists of two digits: the first digit represents the dust protection level, and the second digit represents the water protection level. Here are the common IP ratings:

For example, IP68 means the device is completely dustproof and can withstand long-term immersion in water (usually deeper than 1 meter).

All ALOVA products are dustproof and waterproof.

Typically, the lead time is between 3 to 6 weeks. The exact duration depends on the order size and the specifics of the customization.

The current battery in the headphones is the maximum capacity that can fit within the available structural space.

If you require longer usage time, we can recommend other models for you.

Our OEM services enable clients to design products according to their brand requirements without directly participating in the manufacturing process.

We offer five LOGO customization methods: laser engraving, silk screening, hydrographics, UV crystal labels, and metal labels. You can choose the method that best suits your needs.

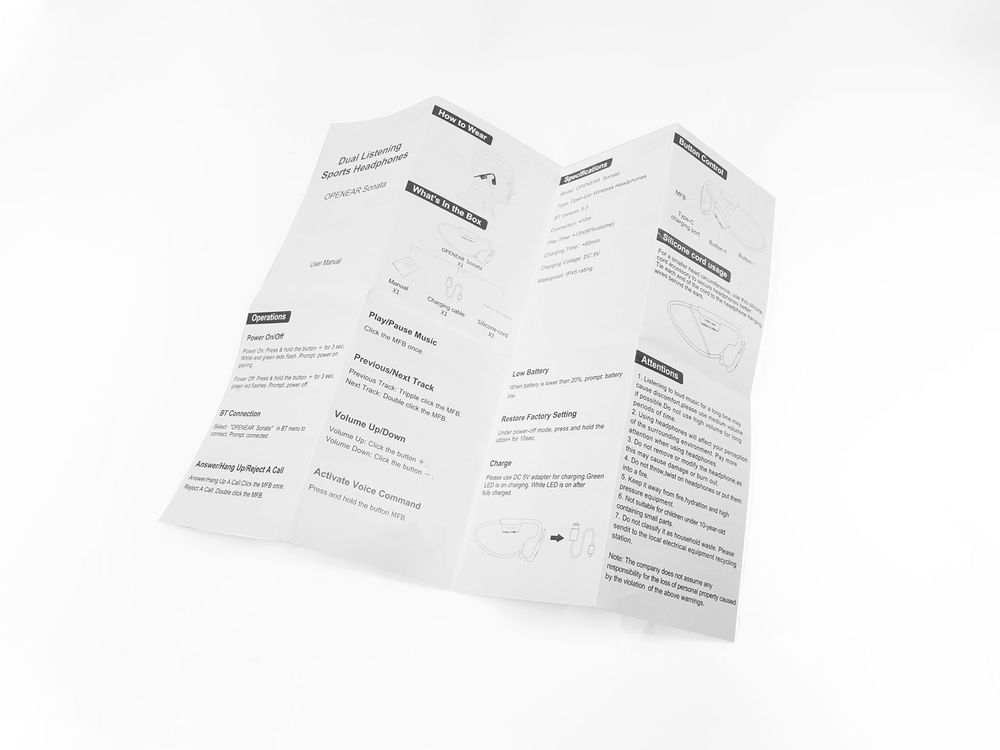

Yes, we support comprehensive packaging customization. This includes five types of packaging forms, three material options, two printing techniques, as well as nine accessory options and three types of instruction manuals. All can be personalized according to your requirements.

The order process includes the following steps:

Typically, the lead time is between 3 to 6 weeks. The exact duration depends on the order size and the specifics of the customization.

Yes, we support exclusive distribution agreements for specific regions. Please contact us for detailed policies and arrangements.

You need to provide the following:

Our minimum order quantity is typically 1,000 units. However, this can be negotiated based on the product type and specific customization requirements.

Yes, we can accept small-batch trial orders depending on the specific circumstances. This helps clients test the market before committing to larger orders.

Yes, our design team can assist you with product design and packaging design to ensure your products meet your brand’s aesthetic and functional requirements.

We support various delivery methods. Please provide the recipient’s address, and we will recommend the most suitable shipping option for your needs.

With an experienced R&D team, by comabining marketing, design and technical services, ALOVA helps clients maximize brand value, expand product portfolio and provide professional & efficient services.

ODM (Original Design Manufacturing) services are comprehensive solutions we provide to clients, covering everything from product design to production.

You need to provide product concepts, design requirements, functional specifications, and market positioning information.

The order process includes the following steps:

Absolutely! We welcome clients to provide design concepts and collaborate with us to develop unique products.

Yes, our design team can provide technical support and design recommendations to assist you in creating your products.

Our minimum order quantity for ODM is typically 3,000 units, but this can be negotiated based on the product type and specific requirements.

The development cycle usually ranges from 14 to 22 weeks, depending on the complexity of the design and production requirements.

We recommend providing the initial design proposal within 1-2 weeks after project initiation to ensure timely progress in development.

We value our clients’ intellectual property and will sign a confidentiality agreement to ensure the safety of your designs and information.

We will provide design samples or 3D models for your confirmation. Once approved, we will proceed to the production phase.

ALOVA (Shenzhen Alex Technology Co., Ltd.), founded in 2014 and based in Shenzhen, China, is an innovative technology manufacturer specializing in open-ear audio solutions, including air conduction headphones, bone conduction headphones, and bone conduction hearing aids.